| About NQE |

| Contact Us |

| Our Clients |

Oil and Grease Separators

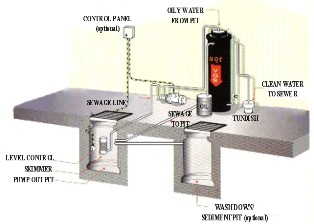

The VGS oil and grease separators from NQ Environmental are a major breakthrough in separation. Together with the separator we can provide you with the specific separation equipment you will need. The VGS separators can be used in car washes, service stations, mining facilities and many more industries!

Contact us. We are certified to be trained and endorsed in the design and installation of the VGS Oily Water Separator to help you find the right VGS separator for your requirements.

The VGS (Vertical Gravity Separator) has been developed to effectively remove free oil, grease and suspended solids from wastewater plus greatly reduce the frequency and difficulty of maintenance compared to conventional plate separators.

The VGS

> continuously meets the performance standards

> is able to handle high concentrations of oil

> effectively removes the suspended solids

> reduces vapour content to acceptable levels

> requires less floor spaceThe VGS is a flooded system in which the inlet and outlet columns form a U-tube configuration such that the oil is trapped on one side of the main body, while the cleaned water flows out of the other side.

The main body contains a continuous truncated conical spiral pack (SPAK) which is made of olephilic material. Oily water is delivered into the bottom of the main body where it flows upwards through the centre of the SPAK assembly.

At the top of the main body, free oil and low density suspended solids are held, which eventually flow out for collection and suitable disposal.

The partially cleaned water is directed to the outside perimeter of the conical SPAK and follows a tortuous pattern while cascading down and around the SPAK.

Here the lower density fluid (oil) is drawn up the incline of the olephilic surface of the SPAK and back into the low pressure centre of the VGS, where it commingles with the incoming fluid and is redirected to the top of the main body.

A continuous convention is created within the SPAK by the density and pressure variation down the fluid column and the upward flow of the cleaned water will enter the output leg of the separator and will flow up and out of the system, whilst the heavy solids will drop to the base of the vessel.

> Panel Beaters

> Car Detailers

> Mechanical Workshops

> Service Stations/Fuel Depots

> Loading Bays> Auto Dismantlers

> Equipment Hire Companies

> Radiator Repairs

> Commercial Car Washes

> Engine Reconditioners

For Enquiries/Orders please see our contact us page

The VGS Grease Separator revolutionizes the on-site pre-treatment of greasy wastewater generated by the preparation of food. This system has been developed to continuously and effectively remove solid and emulsified grease, fats and oils from wastewater.

By nature of its design the VGS Grease Separator is fully automatic in it’s day to day operations with a combination of solenoid valves and electronic timers controlling the self-cleaning and back-flushing cycles on a regular basis.

Click on image to enlarge

The VGS

> reduces BOD’s levels

> reduces Suspended Solids levels

> reduces Ammonia levels

> reduces Phosphorous levels

> reduces Sulphate levels

> reduces Nitrogen levels

> reduces acceptable pH levelsBy installing a VGS Grease Separator into a Food Retail Business the customer, the

water authority and the environment all benefit:

- Reduced cleaning frequency of the grease trap thereby reduced grease trap

maintenance costs- Less drain blockages therefore reduced plumbing costs

- Reduced water authorities fees & charges for non-compliance with local

acceptance standards- Reduced loading on sewage treatment plants

- Increased awareness of environmental issues. By reviewing in-house procedures

for washing floors etc. staff become aware of the impact.

For Enquiries/Orders please see our contact us page

The ICSEP is a system that utilizes the Hydrocyclone technology, a Vertical Gravity Separator and a Downstream Enhancement Vessel. By combing these technologies we are able to separate free oil and suspended solids, and also remove small droplets of oil that are trapped in the water column and don't readily travel to the surface. The ICSEP removes the suspended oils and solids from the water column, whilst the VGS treats the surface oils and solids.

The ICSEP

> is a lower capital cost investment

> continuously meets the performance standards and overcomes many of the problems encountered with more conventional separation technologies

> eliminates compels sludge handling

> minuses use of chemical and flocculants

> requires less floor space

> reduces maintenanceThe ICSEP system naturally aspirates air into the oil/water stream prior to the pump. As this mixture is forced through the patented cyclone, the air and oil droplets are sheared and then dynamically mixed with the water and suspended solids.

The homogenous mixture is discharged into the DEV (Downstream Enhancement Vessel), where rapid gravitational separation takes place. The air encapsulated oil droplets and suspended solids move to the surface and are then returned to the main pit via a skimmer. The main pit is continually treated by a VGS (Vertical Gravity Separator), which continuously skims the free oils out of the pit.

> Car, Truck, Bus and Train Washes

> Refineries

> Power Stations/Fuel Depots

> Mining Facilities

> Fish Farms and Processing

> Industrial and Railway Workshops> Ground Remediation

> Site Decommissioning

> Underground Tunnels

> Steel Works

> Textile Industry

> Marinas

For Enquiries/Orders please see our contact us page